Hangzhou Zhiyu Magnetic Technology Co., Ltd. is China

Rare-earth magnet manufacturers and

Radial magnet factory.

Hangzhou Zhiyu Magnetic Technology Co., Ltd. is located in Tonglu County, Hangzhou City. It mainly focuses on the research and production of samarium cobalt permanent magnetic materials and magnetic components, and also sells magnetic steel and magnetic components such as neodymium iron boron and aluminum nickel cobalt.

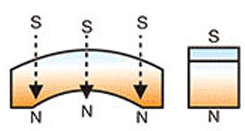

The products are widely used in industries such as national defense and military, aerospace, permanent magnet (high-speed) motors, hydrogen energy compressors, automotive electronics, 5G communication, petrochemical, instrumentation, etc.

The variety of samarium cobalt products is complete, with an annual production capacity of over 200 tons;

Fully covering the entire series of samarium cobalt grades of 1:5 and 2:17, covering the entire series of Br0.5T-1.2T;

Stable production of high-performance samarium cobalt magnetic steel with Br ≥ 1.16T and Hcj≥25KOe;

Stable production of Br≥0.96T low-temperature coefficient series products, with residual magnetic temperature coefficient a<-0.01%;

Stable production of ultra-high temperature (temperature resistance ≥ 550 ℃) and high Br (Br ≥ 1.02T) samarium cobalt magnetic steel;

Provide one-stop services from design to product application.

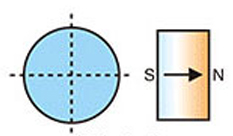

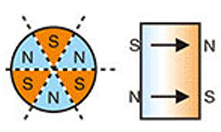

Sintered Samarium Cobalt magnet is prepared by the raw materials being melted under vacuum or inert gas atmosphere in an induction melting furnace and processed in the strip caster and thus cooled to form alloy strip. The alloys are crushed and pulverized to form a fine powder with an average particle size of 3 microns. The powder is subsequently compacted in an aligning field. Densification and the adjustment of magnetic properties are accomplished via sinter, solution and aging processes. The blanks are then machined to the specific shapes and magnetized.

英语

英语 日语

日语 德语

德语