What are the characteristics of high-performance SmCo magnets?

High-performance SmCo (samarium cobalt) magnets exhibit several characteristics that distinguish them from standard SmCo magnets. Here are some key characteristics of high-performance SmCo magnets:

High Magnetic Strength: High-performance SmCo magnets have exceptionally strong magnetic properties, providing a high magnetic energy product. They can generate strong magnetic fields, making them suitable for applications that require robust magnetic performance.

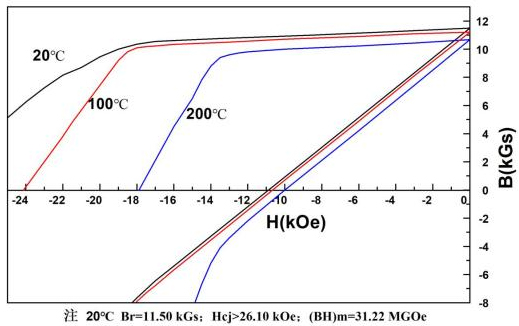

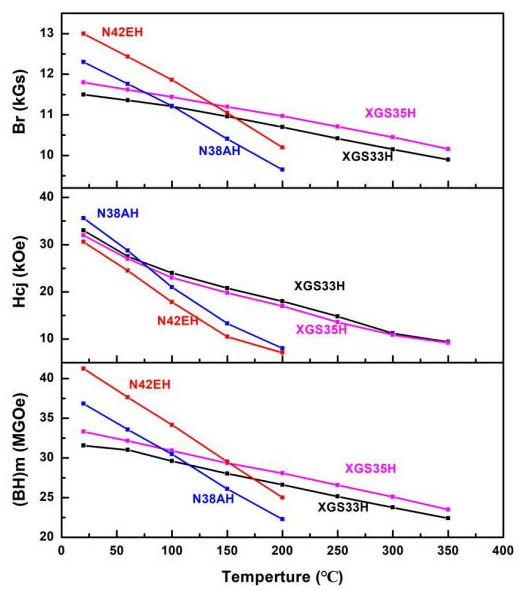

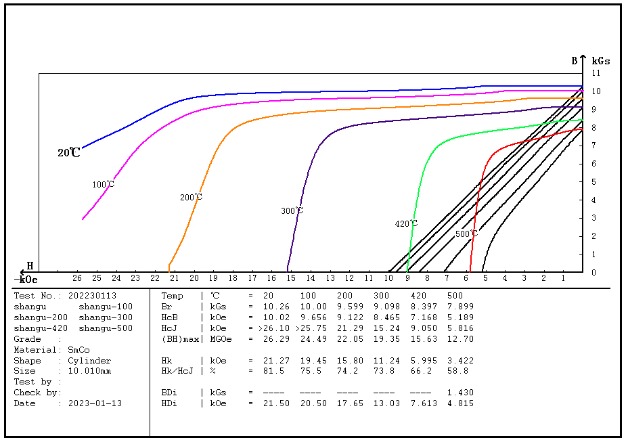

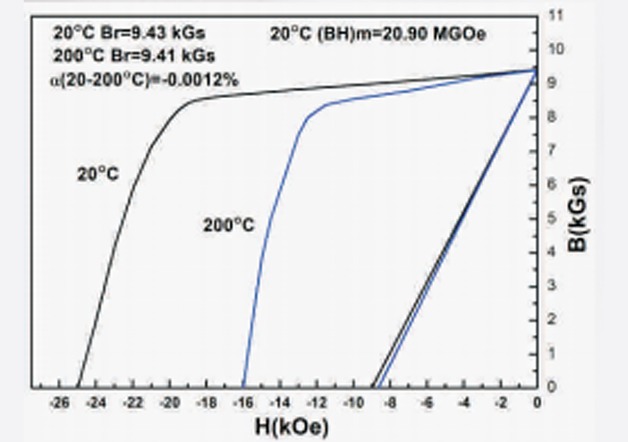

Enhanced Temperature Stability: High-performance SmCo magnets exhibit superior temperature stability compared to standard SmCo magnets. They can maintain their magnetic properties at elevated temperatures, typically with a higher Curie temperature (around 800 degrees Celsius). This property enables their use in high-temperature environments where other magnets may lose their magnetic strength.

Excellent Coercivity: Coercivity refers to a magnet's ability to resist demagnetization. High-performance SmCo magnets possess a high coercive force, allowing them to retain their magnetic strength even when exposed to external magnetic fields or mechanical shocks. This property ensures their reliability and stability in demanding applications.

Superior Corrosion Resistance: High-performance SmCo magnets typically exhibit enhanced corrosion resistance. They are less susceptible to degradation or damage caused by exposure to moisture, humidity, or certain corrosive environments. This property contributes to their longevity and reliability in various applications.

Customizable Shapes and Sizes: High-performance SmCo magnets can be manufactured in various shapes and sizes, enabling customization for specific application requirements. This flexibility in design allows for optimal integration into diverse systems and devices.

Precision and Tight Tolerances: High-performance SmCo magnets can be produced with precise dimensions and tight tolerances. This ensures consistent magnetic performance and facilitates their integration into assemblies or systems with critical dimensional requirements.

High Cost: Compared to other magnet materials, high-performance SmCo magnets tend to be relatively expensive. The cost is primarily attributed to the scarcity of the raw materials and the complex manufacturing process involved in producing magnets with exceptional performance characteristics.

High-performance SmCo magnets find applications in industries such as aerospace, defense, motors and generators, sensors, high-temperature devices, and other demanding environments where strong magnetic fields, temperature stability, and reliability are crucial factors.

What are the applications that require high-performance SmCo magnets?

What are the characteristics of high-performance SmCo magnets?

High-performance SmCo (samarium cobalt) magnets exhibit several characteristics that distinguish them from standard SmCo magnets. Here are some key characteristics of high-performance SmCo magnets:

High Magnetic Strength: High-performance SmCo magnets have exceptionally strong magnetic properties, providing a high magnetic energy product. They can generate strong magnetic fields, making them suitable for applications that require robust magnetic performance.

Enhanced Temperature Stability: High-performance SmCo magnets exhibit superior temperature stability compared to standard SmCo magnets. They can maintain their magnetic properties at elevated temperatures, typically with a higher Curie temperature (around 800 degrees Celsius). This property enables their use in high-temperature environments where other magnets may lose their magnetic strength.

Excellent Coercivity: Coercivity refers to a magnet's ability to resist demagnetization. High-performance SmCo magnets possess a high coercive force, allowing them to retain their magnetic strength even when exposed to external magnetic fields or mechanical shocks. This property ensures their reliability and stability in demanding applications.

Superior Corrosion Resistance: High-performance SmCo magnets typically exhibit enhanced corrosion resistance. They are less susceptible to degradation or damage caused by exposure to moisture, humidity, or certain corrosive environments. This property contributes to their longevity and reliability in various applications.

Customizable Shapes and Sizes: High-performance SmCo magnets can be manufactured in various shapes and sizes, enabling customization for specific application requirements. This flexibility in design allows for optimal integration into diverse systems and devices.

Precision and Tight Tolerances: High-performance SmCo magnets can be produced with precise dimensions and tight tolerances. This ensures consistent magnetic performance and facilitates their integration into assemblies or systems with critical dimensional requirements.

英语

英语 日语

日语 德语

德语